Iwspect Oy

Coordination of manufacture operations for

everything welding related

Operation policy

Iwspect Oy’s quality and safety regulations are ISO 9001, ISO 17025 and ISO 45001 standards compliant.

Quality, work safety and everything related are company’s priority when operating.

In our work we follow the law, current standards, directives and requirements set by our client.

When implementing our customer’s plan, we use new and inventive solutions that particularly benefit our customer.

Our goal is satisfaction of our customer and cost-effectiveness operation.

SERVICES

Iwspect Oy offers project- and expert consulting services: Steel structure-, offshore-, shipbuilding-, crane-, pressure equipment manufacture and so on.

Our experts are experienced in projects implementation, identifying key challenges and goals set by customers are always starting point of the work.

Qualifications of our experts are rated by third party companies.

Among other thing our services include:

– coordination of welding and inspection IWT / IWE / IWI

– construction and maintenance of quality systems (ISO 9001, ISO 14001, ISO 45001, EN 1090, ISO 3834, PED)

– documentation of pressure equipment and metal structures manufacture (final documentation of project according to demands of a buyer)

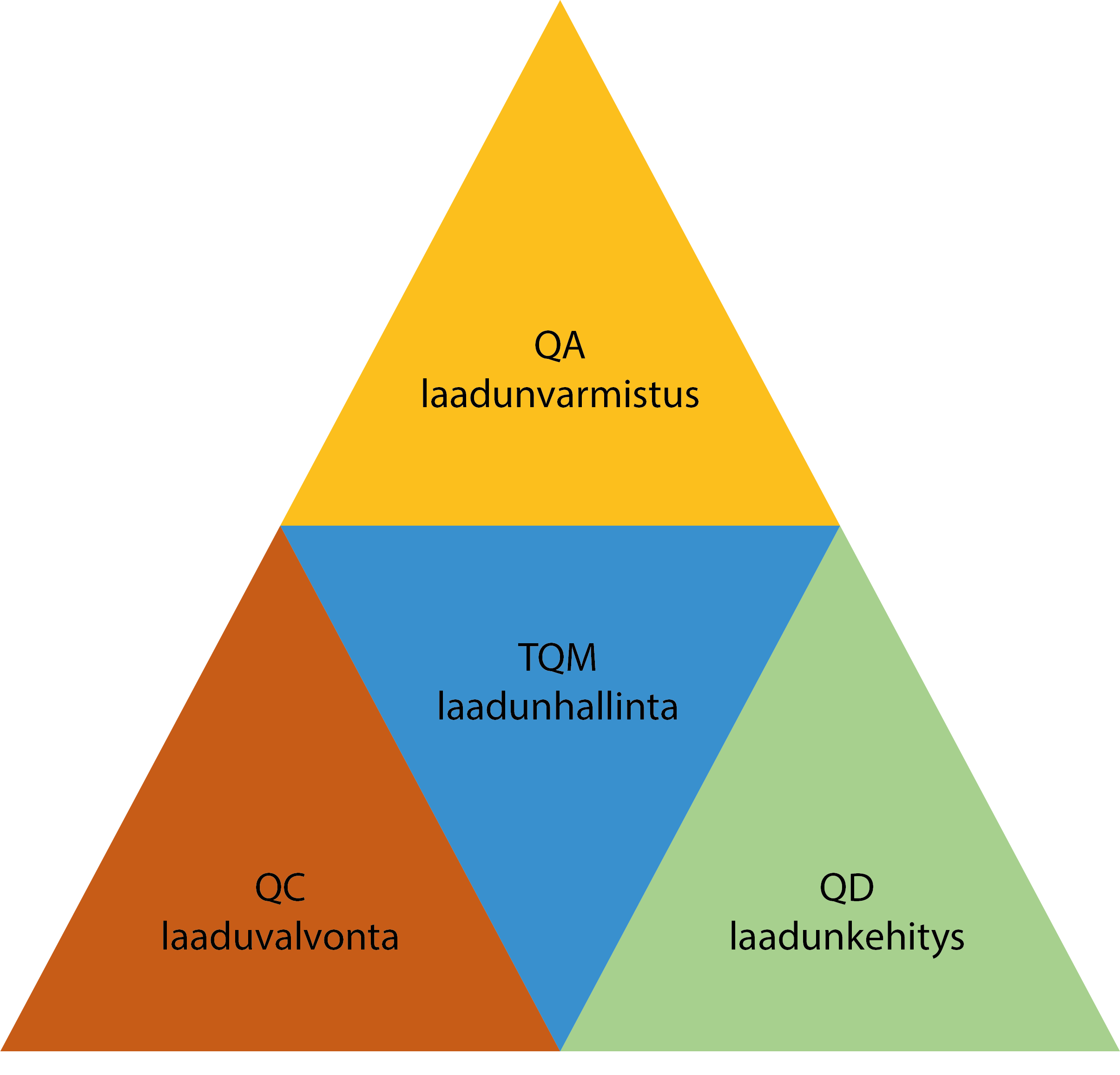

– quality confirmation- and quality control QC / QA (manufacture- and installation supervision)

– planning and inspection of NDT*

– supervision of work. Coordination and organizing of subcontractor

– training related to welding (visual inspection, NDT, welding processes and so on)

– technical- and translation services (Russia-Finland-England)

We have wide experience of subcontractor’s network. We offer help and advice in selection of them.

WELDING COORDINATION

We offer welding coordination services according to standards of SFS-EN ISO 14731

– inspection of requirement- and technical plans. Compiling of quality-, welding- and audit plans.

– negotiation of inspection- and welding production method suitability

– qualification of welders and welding methods in accordance with the Pressure Equipment Directive (PED 2014/68 / EU)

– development and maintenance of welding production and inspection

– welder training

– inspection and testing before welding, during welding and after welding

– development of inspection procedure, upkeep and so on

An external welding coordinator is inexpensive method in many companies and projects. It does give our customer opportunity to decrease costs and receive flexibility and swift response ability.

Our experts are level 3/C certified welding coordinators (IWE / IWT), for example, we are able to coordinate welding according to the standard EN 1090 in order to achieve EXC4 implementation class.

HSEQ- COORDINATION

We offer HSEQ- Coordination services.

HSEQ coordinator gives your company new ways to develop and maintain management system of your company.

HSEQ coordinator is responsible for quality, work safety and environment related development program coordination. He also develops operation meters.

NDT INSPECTION

NDT-inspection (non-destructive testing) helps secure quality of the product and makes sure the product is in accordance with requirement.

We are higly expirienced with different inspections and inspection methods. Inspectors are certified by standard SFS-EN ISO 9712 by third party company.

We do following NDT-inspections:

– visual testing (VT)

– penetrant testing (PT)

– magnetic particle testing (MT)

– ultrasonic testing (UT)

CONTACT

We’ll get back to you as soon as possible